As we have stated in previous articles, feed is the single most significant aspect of aquaculture, either because of its relationship with sustainable aquaculture or simply because it is the highest cost, representing up to 70% of variable costs and between 40 and 60% of total production costs, feed is the first element of production that needs to be attended and managed.

Managing feed is harder than one might think. There is a significant strategic component regarding the time, quantity, quality, and kind of feed to be administered to your pond. In this paper, we will review the characteristics that good feeding management should entail, how to evaluate if I’m feeding enough, and if it’s better to serve cheaper low-quality feed or a more expensive high-quality one.

Feeding is an exciting and complex part of shrimp aquaculture, and we don’t intend to cover all aspects of nutrition, ingredient sourcing, diet formulation, feed production, etc. that compose it; we intend only to cover in a general manner the most significant aspects a farmer should know when selecting a commercial feed and how they can improve their farm management.

Feed composition

Feed quality is always associated with the composition in terms of macro and micronutrients, the ingredients and their source, their effect on the development of shrimp (both growth and survival), and their impact on the final product’s taste.

In general, two primary feed components will determine their quality and cost: protein and fatty acids content and composition.

Protein is the main component of muscles, which is the organ that will be eaten and thus determine the quality of our shrimp in terms of turgor, flavor, color, and shape. Proteins are complex molecules formed by the union and folding of several amino acids.

Different species of shrimp require different amounts and types of protein. Protein is one of the most costly elements of feed; thus, the more protein is added, the higher the cost; this is one of the reasons why shrimp production worldwide has shifted from Black tiger shrimp (P. monodon), which has a protein requirement of around 50%, to white shrimp (P. vannamei) which requires only about 25% of protein in the diet.

There are millions of different possible protein formations, and not all kinds are adequate for shrimp nutrition. Since most aquaculture shrimp come from a marine environment, the first source of protein that was added to pelletized feed was fishmeal. As we have mentioned in previous papers, fishmeal is not a sustainable ingredient and limits the growth of the industry.

Fatty acids are another significant macronutrient in the shrimps’ diet. In terms of proportion, lipids are not as substantial as protein, composing between 5 and 12% of the diet; but they are just as crucial since this nutrient is present in several metabolic functions. In this case, the composition of the chain is even more important than that of the protein’s formation, especially regarding essential fatty acids (EFA), phospholipids, sterols, and carotenoids, which are required for growth, survival, and the normal metabolic function.

Just as what happens with protein, EFA are sourced mainly from fish oil, which is obtained from reduction fisheries, limiting the ability of the industry to grow. The case of fatty acids is even more delicate than the protein one since the sources of the specific EFA needed by shrimp (the n-6

and n-3 families of fatty acids like linoleic and linolenic acids, and the highly unsaturated fatty acids or HUFA, like arachidonic and eicosapentaenoic acids) are more challenging to substitute than proteins.

Handling and storage

The most significant aspect determining the handling and storage methods is the feed’s production method.

Whether it is fresh, pelletized, extruded, flaked, lyophilized, or any other method, each aquafeed product has its advantages and disadvantages and determines the management difficulty.

The single most used feed production system is pelletization. This process consists of compressing particles into pellets, eliminating the humidity of the feed, and making its storage and handling easier. Furthermore, this system is the least costly in terms of production, thus making it cheaper for producers. Despite these benefits, this method also has some disadvantages; for example, the heat and pressure applied during the process can change the diet’s nutrient composition, sometimes reducing its performance. Another problem is the sedimentation and decomposition of excess feed. This practice is the most significant source of ammonia in the water, reducing water quality and increasing production costs.

One current that is presently growing is the use of bacteria, yeasts, fungi, and other organic components that can grow easily and cheap in the pond through different management systems (such as biofloc or aquamimicry), or directly in the feed by a fermentation process (also known as predigested feed). These methods produce better results, but storage and handling can be complex, especially in large farms; this obstacle can be overcome by sound knowledge, inventory control, and qualified personnel.

In conclusion, a farmer must evaluate their capacity to manage and store feed and the quality and experience of their staff to select the kind of feed that best fits their farm’s activity.

Administration

Feed administration needs to answer three questions: how, how much, and when to feed. Let’s start with the how.

There are several ways one can feed their shrimp, and the best method depends on the farmer’s infrastructure, capacity, capital, and experience. The cheapest way of feeding is by manually administrating feed. The key aspect of manual feeding is trying to ensure that the pellets are administrated in a homogeneous way along the pond; this way, all individuals would have the chance to eat. It’s important to know that wind and pond currents will tend to accumulate feed in specific tank zones, so if it’s not administrated homogenously, these accumulations can become more significant. Large amounts of feed in one spot mean less availability for all shrimp and a larger probability of having uneaten feed, which is costly and can deteriorate water quality.

Manual feeding in small circular tanks is easier and consists simply of rounding the tank while spreading the feed. In larger ponds, farmers tend to use small boats to cover all the production area. In the case of ponds, farmers must resist the urge of just giving the feed in the pond’s docks, which are designed mostly for measuring.

Automatic feeding is a better option, although it entails a larger capital investment. There are several kinds of automatic feeders, from completely automated to semiautomatic blowers. Fully automated feeders consist of reservoirs connected to a blower over a floating stand placed on the center of the pond; one can program the hours and amounts of feed to distribute and include a blower for dissemination. In the case of smaller tanks, there are options of simpler, cheaper feeders that don’t have the dissemination capacity, but this problem can be overcome by using and controlling the pond’s water current.

Semiautomatic feeders (or feed blowers) consist of air pumps connected to a hose and a feed reservoir; when the blower is on, feed is expelled at large distances and continuously. This allows to feed faster and more homogenously, but transport and labor are needed for the equipment to function. This technique is used in places where labor is cheap, and farms are considerably big.

We now know different ways of feeding our shrimp, and now we have to deduce how much we should give.

Feeding shrimp is almost an art; several factors determine the amount of feed to give: from the temperature to the biomass passing through the composition and type of feed. To guide farmers, aquafeed producers developed a series of tables or charts that state the amount of feed to give during different production periods. Although these charts serve as a starting point, each farmer needs to adjust the feed given to maximize profits.

As stated in the paragraph above, dynamic factors (such as temperature, salinity, the hour of the day, or health) affect the eating ratio of shrimp, so producers need to monitor if their strategy is functioning. There are two main indicators to monitor this aspect of production. The first one is a qualitative system in which producers use submerged trays that are surfaced to look for the presence of shrimp, their behavior, and the amount of feed in the tray after a certain time has elapsed since they were last fed. This way, if too much feed is found in different trays along the pond, they’re feeding too much, and the other way around, if there is no feed, it might be time to increase the ration.

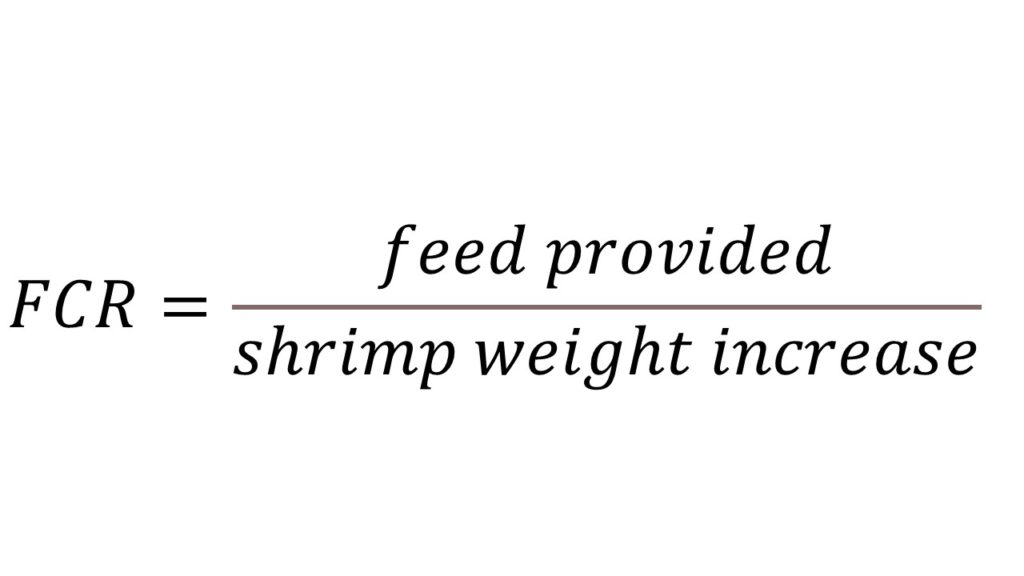

The main quantitative partial indicator of overfeeding is the feed conversion ratio (FCR), which can be calculated as follows.

It’s essential that both terms of the ratio are provided for the same period of time. If a farmer wants to know the performance over the full production cycle, then they should add the total amount of feed used and the total weight of shrimp harvested; if, on the contrary, they want a weekly FCR, then they should only add the feed provided during the week analyzed and the weight gained in that same week (that is the weight at the end of the week minus the weight at the beginning of the week).

The FCR is nothing but an indicator of the shrimp’s weight gain per unit of feed provided, so the smaller the FCR is, the better the farm is performing, i.e., an FCR of 1.5 means that for each kg of shrimp gained, one has provided 1.5 kg of feed. If we find large FCR numbers, say 3 or 4 for shrimp, that means that we are providing way too much feed. A well-managed shrimp farm should aim for FCRs of between 1 and 2 (sometimes even less than one when bioflocs are used as complementary feed). This indicator must be used carefully and only to look for overfeeding; it is no use to know if we are underfeeding. Both qualitative and quantitative methods are complementary to adjust the values from the feed manufacturer feeding charts.

Once we have pinpointed what, how and how much to give, we need to select when to feed.

First, we need to establish the number of rations to provide. It is not the same to deliver 600 kg per hectare once a day as providing 100 kg per hectare every 4 hours, even if the resulting amount equals 600 kg per day. Shrimp, like any other organism, has a limit of how much feed they can ingest in a certain period; if too much feed is given in one ration, only a portion of it will be eaten, and the rest of it will dissolve, decompose and deteriorate the pond’s water quality. At the same time, if the portion of feed is divided too much (say every 10 minutes), the distribution of the feed will not be homogeneous, not all shrimp will be able to eat, and the logistics of it can be difficult. Therefore, a farmer must select the timelapse that best fits their farm. That being said, feeding every 3-5 hours is a common practice in shrimp farming.

Finally, the time of the day we decide to feed is not trivial; let us remember that, biologically, shrimp prefer to eat at dusk and night; this doesn’t mean that they won’t eat in the morning, so the proper monitoring of the factors mentioned above (trays and FCR) would help knowing if it’s best to give the same amount of feed each serving or if less feed should be given during daylight and a bigger ration at night.

Selecting a feed provider

Finally, but not less important, we will talk about how to select a feed, which is mainly driven by costs, and by this, we don’t mean the cost per kg of each different brand, but what a farmer should look into before selecting the feed that best performs in their farm.

In aquafeed, as in most products, you get what you pay. This doesn’t mean that the most expensive feed is the best for your farm, but the cost isn’t the only aspect that should be considered when selecting a feed brand.

To correctly select a feed brand, one must look into their performance graphs. Usually, feed brands have R&D departments that test their feed and their performance. In the end, we need to see how much we are getting for each dollar invested in feed. The best way to describe this is through an example.

Let’s assume that we have a farm, and we are choosing between three brands of feed with different compositions, production methods, and prices. We decide to perform an experiment, feeding one-third of the farm with feed A, one-third with feed B, and the final part with feed C, obtaining the following results.

| Price (USD/kg) | Avg. harvest size (gr) | Feed provided (avg. gr per shrimp) | FCR | Unit feed costs (USD/shrimp) | Price (USD/kg) | Avg. unit income | Avg. Unit profit | |

| Feed A | 0.5 | 23 | 37.55 | 1.63 | 0.019 | 5 | 0.12 | 0.096 |

| Feed B | 0.7 | 22 | 23.01 | 1.05 | 0.016 | 4.8 | 0.11 | 0.089 |

| Feed C | 1.1 | 29 | 31.21 | 1.08 | 0.034 | 5.2 | 0.15 | 0.111 |

We seeded at the same time and density and provided the rations dictated by the feed manufacturers, maintaining production for the same number of days. At first, one might go for Feed A for having the lowest price overall; it might need a little more feed per ration, but the low cost might justify this; furthermore, it achieved 23-gram shrimp with a higher market value than the ones obtained with feed B. On the other hand, feed B needs less feed per shrimp in a production cycle; also, it shows an impressive 1.05 FCR, resulting in the lowest unit feed cost when compared to feed A and C, but in the same period, it achieved 22-gram shrimp, with a market value of 4.8 USD per kg. Finally, Feed C has the highest cost, more than double of Feed A and 36% more than Feed B; furthermore, the FCR obtained is 1.08 resulting in the highest unit feed cost value of all three, but the high quality of the ingredients allowed it to get 29-gram shrimp, which have the highest market value.

At first glance, Feed C looks like the worst option (not the best FCR, the highest unit feed cost, and the highest price). Still, let’s analyze and look a little closer. We can see that the difference in weight gain associated with the higher market value results in the highest average unit profit (0.015 cents more than Feed A and 0.022 cents more than Feed B), which means that investing in Feed C would result in the highest profitability, therefore, the best way to go for a farm that doesn’t have liquidity issues is, definitely, Feed C. On the other hand, if there is not enough capital for inputs, a farmer might go for Feed B; although it’s the worst option in terms of profitability, it is also the one that gives the smallest unit costs due to the reduced amount of feed needed as compared to Feed A, which is cheaper in a per kg bases. Since Feed A requires a lot of feed to achieve sustainable growth, it is the worst option of those presented in this example.

It’s important to remark that this is only an example and not always the most expensive products are the ones that perform best. The idea of this exercise is to show how a shrimp farmer should do a feed analysis before selecting a brand for the following production cycles, and showing how sometimes, the most relevant information is the one obtained after a thorough review of the data obtained and this allows better decisions to be made.

As we have discussed along the lines in this paper, feeding is the single most significant element of shrimp production in terms of adjusting costs and getting a profitable farm. We have tried to present different options and the current trends in shrimp aquaculture, although it’s essential to keep in mind that each farm has its peculiarities, and they need to be studied and understood by the farmer through the analysis of their historical production data to get a better picture of how to manage their farm achieving the higher productivity and profitability possible.

I want to learn and know more about the proper breeding and nutrition of technical shrimp with the vital processes of establishing farms